埃馬克生產(chǎn)系統(tǒng):

適合差速器外殼的高效加工解決方案

Production system by EMAG:

High-performance solutions for differential cases

根據(jù)麥肯錫公司最新的一項(xiàng)調(diào)研預(yù)測,至 2030 年,全球汽車產(chǎn)量的年增長率為百分之二。以差動傳動裝置為例,如何在保證達(dá)到高質(zhì)量要求的同時,也滿足日益增加的產(chǎn)量要求:無論使用何種驅(qū)動系統(tǒng)設(shè)計,該核心組件均必不可少。換言之,差速器殼體的產(chǎn)量將持續(xù)增加。同時,差速器外殼的加工要求也極其嚴(yán)格。埃馬克集團(tuán)在這個領(lǐng)域中已處于優(yōu)勢地位:這家專業(yè)制造商研發(fā)包括倒立式車削中心、工件輸送系統(tǒng)解決方案和夾具在內(nèi)的完整生產(chǎn)線,從而能為用戶提供差速器外殼的高效加工整體交鑰匙解決方案。

The worldwide production of motor vehicles is set to rise by about two percent every year until 2030, according to the estimates of a new McKinsey study. An excellent example of how to handle these rising production volumes despite stringent quality requirements can be found in the differential: This key component will remain indispensable whatever the propulsion system used by the vehicle. In other words, production volumes of differentials will continue to rise. At the same time, the machining required for parts like the differential case can be very demanding. The EMAG Group is well positioned in this environment: Its specialists develop complete production lines including vertical turning centers, automation solutions, and clamping devices. The user receives a turnkey, high-performance production solution for differential cases.

在汽車制造行業(yè)中,差速器殼體始終是生產(chǎn)規(guī)劃人員關(guān)注的重點(diǎn)。一方面,無論汽車使用內(nèi)燃機(jī)、電動機(jī)還是混合動力發(fā)動機(jī)進(jìn)行驅(qū)動:過彎時用于平衡兩個車輪之間轉(zhuǎn)速的車橋差速器總是不可或缺的。另一方面,工件種類繁多,并且全部需要高效可靠地進(jìn)行生產(chǎn)。以差速器外殼為例:差速器外殼有內(nèi)部為球形或半球形的封閉式殼體,也有配備蓋子的“開放式”殼體,這些不同的形狀會影響加工工序。但無論是哪種情況,都需要分為多道相互協(xié)調(diào)、依次執(zhí)行的子工序進(jìn)行加工。設(shè)計制造此類整體系統(tǒng)便是總部位于薩拉赫的埃馬克集團(tuán)這樣的專業(yè)制造商的任務(wù)。“我們?yōu)楦鞣N差速器外殼的加工研發(fā)完整的解決方案。方案中所采用的工藝技術(shù),包括倒立式車削中心、夾具和連線裝置,均來自埃馬克。客戶可向埃馬克中心聯(lián)系人一對一提出所有要求,然后將整個項(xiàng)目規(guī)劃工作外包給我們。我們可以為客戶提供經(jīng)過完美協(xié)調(diào)的整體式系統(tǒng)——節(jié)拍僅 95 秒、場地需求小、工藝可靠性高,”埃馬克的模塊化解決方案技術(shù)銷售經(jīng)理兼差速器外殼技術(shù)專家 Daniele Loporchio 解釋說。

The differential case is still a constant focus of attention among production planners in the automotive industry. For one, it doesn't matter whether the vehicle is powered by a combustion engine, an electric motor, or a hybrid engine: They all require an axle differential that compensates the speed between the two wheels during turns. On top of that, there are different versions of the component that all need to be manufactured efficiently and reliably. Take the differential case, for example: There are closed cases with a spherical or hemispherical internal shape, and “open” cases with a lid. These shapes have an effect on the machining sequence. In all cases, however, a number of subprocesses are required which need to be carried out in a perfectly timed sequence cycle. Creating an overall system that can do this is a job for specialists—like the EMAG Group based in Salach, Germany. “We develop comprehensive solutions for machining different types of differential cases. EMAG supplies all the technology required, including vertical turning centers, clamping devices, and interlinking of machines. Customers discuss their requirements with a single point of contact and outsource the entire project planning to us. The result is a perfectly calibrated comprehensive system with short cycle times of only about 95 seconds, a small footprint, and high process reliability,” explains Daniele Loporchio, Technical Sales Manager Modular Solutions and technology expert for differential cases at EMAG.

四道工序、節(jié)拍僅 95 秒即可達(dá)成目標(biāo)

埃馬克展示的差速器外殼制造系統(tǒng)以其簡單而巧妙的設(shè)計令人印象深刻。為能實(shí)現(xiàn)這一節(jié)拍僅為 95 秒的完整加工工序,各機(jī)床無一例外地采用了埃馬克的模塊化解決方案,并與 TrackMotion 工件輸送系統(tǒng)高效聯(lián)接。

OP 10 / OP 20:車削差殼面一側(cè) / 法蘭面一側(cè)

差殼首先在兩臺 VL 4 車床上進(jìn)行加工。此處將完成軸座和法蘭的內(nèi)部和外部加工。VL 機(jī)床配備具有 12 個刀位的動力刀具刀塔,還可實(shí)現(xiàn)十字軸孔鉆削加工。

OP 30:車削外徑

差速器外殼的剩余外部加工可在一臺 VT 4 車床上通過一次裝夾完成。由此可排除重復(fù)裝夾定位帶來的裝夾誤差。VT 4 配備兩個刀塔,每個刀塔具有 11 個刀位。由此可實(shí)現(xiàn) 4 軸同時加工,從而縮短節(jié)拍。工件的平行上下料也確保縮短非加工時間。

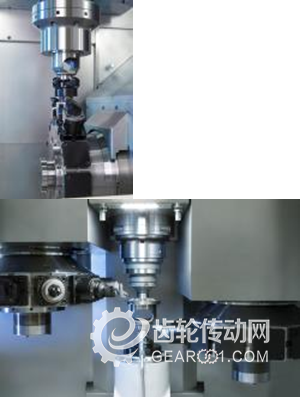

OP 40:精加工

后續(xù)加工在一臺 VL 6立式車削中心上進(jìn)行。在 OP 40 中,埃馬克專為差速器外殼加工而設(shè)計的獨(dú)特夾具(見圖示)是一大亮點(diǎn)。在這道工序中對十字軸孔進(jìn)行精鉸加工,并用鵝頸刀對球頂先進(jìn)行粗加工,然后再進(jìn)行精加工——全部在一次裝夾中完成。

至此僅需要完成最后的質(zhì)檢步驟。此步驟可在一套額外的測量系統(tǒng)上完成,確保每件差速器外殼均具有完美的品質(zhì)。

Job done in four operations with a cycle time of only 95 seconds

What is striking about the manufacturing system for differential cases that EMAG is presenting is its simple and yet ingenious design. To implement such comprehensive machining within a cycle time of only about 95 seconds, the machines used are exclusively based on EMAG Modular Solutions building blocks that are interlinked with the TrackMotion automation system.

OP 10 / OP 20: TURNING OF THE CASE SIDE / FLANGE SIDE

The case is first machined on two VL 4 turning centers. This is where the internal and external machining of the shaft mounts and flanges is performed. Furthermore, the driven tool turret with 12 tool posts on the VL machines enables them to drill cross holes.

OP 30: TURNING OF THE OUTER DIAMETER

The remaining external machining of the differential case is performed with a single clamping operation on a VT 4 turning center. This eliminates the occurrence of positioning errors when changing the clamping position. The VT 4 has two tool turrets with 11 tool posts each, which enables 4-axis simultaneous machining and thus quick processes. Moreover, parallel loading and unloading of components ensures short idle times.

OP 40: FINE MACHINING AND FINISHING

Machining is then performed on a VL 6 pick-up turning center. In OP 40, the imposing clamping device catches the eye. It was specially developed by EMAG to machine differential cases (see image). In this operation, the bore holes are precision machined and the spherical calotte is first rough-machined on the inside with a special tool and then finished—all in a single clamping operation.

All that remains to be done now is final quality control. This is performed on an additional measuring system and thus guarantees that each differential case is of flawless quality.

此外,這套系統(tǒng)的連線也非常高效。基于埃馬克的模塊化和標(biāo)準(zhǔn)化機(jī)床平臺:由于具有統(tǒng)一的傳送高度、軟件控制系統(tǒng)和上下料主軸,可以輕松地使用埃馬克的 TrackMotion 工件輸送系統(tǒng)來連接各臺機(jī)床。配備可編程電動機(jī)械手的升降翻轉(zhuǎn)滑臺可在各臺機(jī)床之間的軌道 (Track) 上來回穿梭,并將差速器外殼放置到輸送帶上。之后,由上下料工作主軸將工件送入和送出加工區(qū)——這是一個非加工時間極短的快速進(jìn)程。還有很重要的一點(diǎn),由于采用緊湊型的立式機(jī)床,整條生產(chǎn)線的占地面積非常小,可輕松訪問及設(shè)置各個模塊。

The interlinking of the machines in this system is also especially effective. It is based on EMAG's modular, standardized machine platform: With their uniform transfer height, software control, and pick-up spindle, the machines can easily be connected using EMAG's TrackMotion automation system. A lifting and flip-over carriage with a programmable electric gripper runs back and forth between the machines on a track and places the differential cases on a conveyor belt. The pick-up working spindle then transports the parts in and out of the machining area, in a rapid process with little non-productive time. Owing to the compact vertical machines, the overall line has a very small footprint, and the modules can be accessed easily for setup.

在市場上取得成功

近年來,這種精簡高效的生產(chǎn)方法越來越成功:在全球范圍內(nèi),已有 60 至 70 條埃馬克生產(chǎn)線、共約 250 臺機(jī)床應(yīng)用于差速器外殼的車削生產(chǎn)。原始設(shè)備制造商和一級供應(yīng)商均信賴這種工藝技術(shù)。“我們提供從機(jī)床到夾具的整套交鑰匙產(chǎn)品。所有組件都已完美協(xié)調(diào)匹配。我們所有的研發(fā)工作都以豐富的實(shí)踐經(jīng)驗(yàn)為基礎(chǔ),這些優(yōu)勢將在市場上得到認(rèn)可,”Loporchio 總結(jié)說。

Successful in the marketplace

In recent years, this slim and efficient approach has enjoyed ever greater success: 60 to 70 EMAG production lines with a total of around 250 turning machines are already in use around the world in the production of differential cases. OEMs and tier 1 suppliers rely on this technology. “We offer the complete package, from machine to clamping device. All the components are perfectly matched. Also, all our development work is grounded in a lot of practical experience. These advantages are gaining recognition in the marketplace,” says Loporchio in conclusion.

相關(guān)信息請見:Https://www.emag.com/de/werkstuecke/differenzialgehaeuse.html 或者親臨 2018 年 AMB 展會 4 號展廳、4B51 號展臺。

You will find more information here: https://www.emag.com/de/werkstuecke/differenzialgehaeuse.html or during a personal meeting at the AMB 2018 at Stand 4B51 in Hall 4.

根據(jù)工件/工藝技術(shù)要求,在收到訂單后約 6 個月,便可向客戶交付一套完整的差速器生產(chǎn)線模塊化解決方案。

A complete differential line based on the Modular Solutions building block can be delivered in only around 6 months after receipt of the customer's order—depending on the component or the technological requirements.

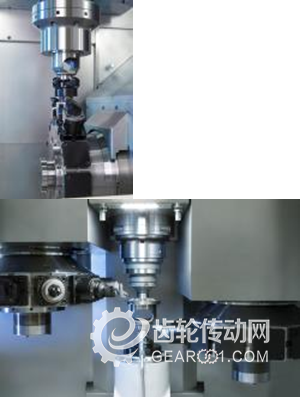

第一面和第二面的車削(OP 10 和 20)在埃馬克 VL 機(jī)床上進(jìn)行,OP 30 在埃馬克 VT 機(jī)床上進(jìn)行。

The first and second sides (OP 10 and 20) are turned on a VL machine, while OP 30 is performed on a VT machine from EMAG.

使用埃馬克的 TrackMotion 系統(tǒng)時,配備可編程電動機(jī)械手的升降翻轉(zhuǎn)滑臺可在各臺機(jī)床之間的軌道 (Track) 上來回穿梭。

With the TrackMotion system from EMAG, a lifting and flip-over carriage with programmable electric gripper runs back and forth on a track between the machines.

另外,高精密特殊夾具也由埃馬克自行研發(fā)。這里展示的是 OP 40 中的 VL 6 車削中心。

The high-end special clamping devices are also developed in-house by EMAG. In this case for the VL 6 turning center in OP 40.

適合差速器外殼的高效加工解決方案

Production system by EMAG:

High-performance solutions for differential cases

根據(jù)麥肯錫公司最新的一項(xiàng)調(diào)研預(yù)測,至 2030 年,全球汽車產(chǎn)量的年增長率為百分之二。以差動傳動裝置為例,如何在保證達(dá)到高質(zhì)量要求的同時,也滿足日益增加的產(chǎn)量要求:無論使用何種驅(qū)動系統(tǒng)設(shè)計,該核心組件均必不可少。換言之,差速器殼體的產(chǎn)量將持續(xù)增加。同時,差速器外殼的加工要求也極其嚴(yán)格。埃馬克集團(tuán)在這個領(lǐng)域中已處于優(yōu)勢地位:這家專業(yè)制造商研發(fā)包括倒立式車削中心、工件輸送系統(tǒng)解決方案和夾具在內(nèi)的完整生產(chǎn)線,從而能為用戶提供差速器外殼的高效加工整體交鑰匙解決方案。

The worldwide production of motor vehicles is set to rise by about two percent every year until 2030, according to the estimates of a new McKinsey study. An excellent example of how to handle these rising production volumes despite stringent quality requirements can be found in the differential: This key component will remain indispensable whatever the propulsion system used by the vehicle. In other words, production volumes of differentials will continue to rise. At the same time, the machining required for parts like the differential case can be very demanding. The EMAG Group is well positioned in this environment: Its specialists develop complete production lines including vertical turning centers, automation solutions, and clamping devices. The user receives a turnkey, high-performance production solution for differential cases.

在汽車制造行業(yè)中,差速器殼體始終是生產(chǎn)規(guī)劃人員關(guān)注的重點(diǎn)。一方面,無論汽車使用內(nèi)燃機(jī)、電動機(jī)還是混合動力發(fā)動機(jī)進(jìn)行驅(qū)動:過彎時用于平衡兩個車輪之間轉(zhuǎn)速的車橋差速器總是不可或缺的。另一方面,工件種類繁多,并且全部需要高效可靠地進(jìn)行生產(chǎn)。以差速器外殼為例:差速器外殼有內(nèi)部為球形或半球形的封閉式殼體,也有配備蓋子的“開放式”殼體,這些不同的形狀會影響加工工序。但無論是哪種情況,都需要分為多道相互協(xié)調(diào)、依次執(zhí)行的子工序進(jìn)行加工。設(shè)計制造此類整體系統(tǒng)便是總部位于薩拉赫的埃馬克集團(tuán)這樣的專業(yè)制造商的任務(wù)。“我們?yōu)楦鞣N差速器外殼的加工研發(fā)完整的解決方案。方案中所采用的工藝技術(shù),包括倒立式車削中心、夾具和連線裝置,均來自埃馬克。客戶可向埃馬克中心聯(lián)系人一對一提出所有要求,然后將整個項(xiàng)目規(guī)劃工作外包給我們。我們可以為客戶提供經(jīng)過完美協(xié)調(diào)的整體式系統(tǒng)——節(jié)拍僅 95 秒、場地需求小、工藝可靠性高,”埃馬克的模塊化解決方案技術(shù)銷售經(jīng)理兼差速器外殼技術(shù)專家 Daniele Loporchio 解釋說。

The differential case is still a constant focus of attention among production planners in the automotive industry. For one, it doesn't matter whether the vehicle is powered by a combustion engine, an electric motor, or a hybrid engine: They all require an axle differential that compensates the speed between the two wheels during turns. On top of that, there are different versions of the component that all need to be manufactured efficiently and reliably. Take the differential case, for example: There are closed cases with a spherical or hemispherical internal shape, and “open” cases with a lid. These shapes have an effect on the machining sequence. In all cases, however, a number of subprocesses are required which need to be carried out in a perfectly timed sequence cycle. Creating an overall system that can do this is a job for specialists—like the EMAG Group based in Salach, Germany. “We develop comprehensive solutions for machining different types of differential cases. EMAG supplies all the technology required, including vertical turning centers, clamping devices, and interlinking of machines. Customers discuss their requirements with a single point of contact and outsource the entire project planning to us. The result is a perfectly calibrated comprehensive system with short cycle times of only about 95 seconds, a small footprint, and high process reliability,” explains Daniele Loporchio, Technical Sales Manager Modular Solutions and technology expert for differential cases at EMAG.

四道工序、節(jié)拍僅 95 秒即可達(dá)成目標(biāo)

埃馬克展示的差速器外殼制造系統(tǒng)以其簡單而巧妙的設(shè)計令人印象深刻。為能實(shí)現(xiàn)這一節(jié)拍僅為 95 秒的完整加工工序,各機(jī)床無一例外地采用了埃馬克的模塊化解決方案,并與 TrackMotion 工件輸送系統(tǒng)高效聯(lián)接。

OP 10 / OP 20:車削差殼面一側(cè) / 法蘭面一側(cè)

差殼首先在兩臺 VL 4 車床上進(jìn)行加工。此處將完成軸座和法蘭的內(nèi)部和外部加工。VL 機(jī)床配備具有 12 個刀位的動力刀具刀塔,還可實(shí)現(xiàn)十字軸孔鉆削加工。

OP 30:車削外徑

差速器外殼的剩余外部加工可在一臺 VT 4 車床上通過一次裝夾完成。由此可排除重復(fù)裝夾定位帶來的裝夾誤差。VT 4 配備兩個刀塔,每個刀塔具有 11 個刀位。由此可實(shí)現(xiàn) 4 軸同時加工,從而縮短節(jié)拍。工件的平行上下料也確保縮短非加工時間。

OP 40:精加工

后續(xù)加工在一臺 VL 6立式車削中心上進(jìn)行。在 OP 40 中,埃馬克專為差速器外殼加工而設(shè)計的獨(dú)特夾具(見圖示)是一大亮點(diǎn)。在這道工序中對十字軸孔進(jìn)行精鉸加工,并用鵝頸刀對球頂先進(jìn)行粗加工,然后再進(jìn)行精加工——全部在一次裝夾中完成。

至此僅需要完成最后的質(zhì)檢步驟。此步驟可在一套額外的測量系統(tǒng)上完成,確保每件差速器外殼均具有完美的品質(zhì)。

Job done in four operations with a cycle time of only 95 seconds

What is striking about the manufacturing system for differential cases that EMAG is presenting is its simple and yet ingenious design. To implement such comprehensive machining within a cycle time of only about 95 seconds, the machines used are exclusively based on EMAG Modular Solutions building blocks that are interlinked with the TrackMotion automation system.

OP 10 / OP 20: TURNING OF THE CASE SIDE / FLANGE SIDE

The case is first machined on two VL 4 turning centers. This is where the internal and external machining of the shaft mounts and flanges is performed. Furthermore, the driven tool turret with 12 tool posts on the VL machines enables them to drill cross holes.

OP 30: TURNING OF THE OUTER DIAMETER

The remaining external machining of the differential case is performed with a single clamping operation on a VT 4 turning center. This eliminates the occurrence of positioning errors when changing the clamping position. The VT 4 has two tool turrets with 11 tool posts each, which enables 4-axis simultaneous machining and thus quick processes. Moreover, parallel loading and unloading of components ensures short idle times.

OP 40: FINE MACHINING AND FINISHING

Machining is then performed on a VL 6 pick-up turning center. In OP 40, the imposing clamping device catches the eye. It was specially developed by EMAG to machine differential cases (see image). In this operation, the bore holes are precision machined and the spherical calotte is first rough-machined on the inside with a special tool and then finished—all in a single clamping operation.

All that remains to be done now is final quality control. This is performed on an additional measuring system and thus guarantees that each differential case is of flawless quality.

此外,這套系統(tǒng)的連線也非常高效。基于埃馬克的模塊化和標(biāo)準(zhǔn)化機(jī)床平臺:由于具有統(tǒng)一的傳送高度、軟件控制系統(tǒng)和上下料主軸,可以輕松地使用埃馬克的 TrackMotion 工件輸送系統(tǒng)來連接各臺機(jī)床。配備可編程電動機(jī)械手的升降翻轉(zhuǎn)滑臺可在各臺機(jī)床之間的軌道 (Track) 上來回穿梭,并將差速器外殼放置到輸送帶上。之后,由上下料工作主軸將工件送入和送出加工區(qū)——這是一個非加工時間極短的快速進(jìn)程。還有很重要的一點(diǎn),由于采用緊湊型的立式機(jī)床,整條生產(chǎn)線的占地面積非常小,可輕松訪問及設(shè)置各個模塊。

The interlinking of the machines in this system is also especially effective. It is based on EMAG's modular, standardized machine platform: With their uniform transfer height, software control, and pick-up spindle, the machines can easily be connected using EMAG's TrackMotion automation system. A lifting and flip-over carriage with a programmable electric gripper runs back and forth between the machines on a track and places the differential cases on a conveyor belt. The pick-up working spindle then transports the parts in and out of the machining area, in a rapid process with little non-productive time. Owing to the compact vertical machines, the overall line has a very small footprint, and the modules can be accessed easily for setup.

在市場上取得成功

近年來,這種精簡高效的生產(chǎn)方法越來越成功:在全球范圍內(nèi),已有 60 至 70 條埃馬克生產(chǎn)線、共約 250 臺機(jī)床應(yīng)用于差速器外殼的車削生產(chǎn)。原始設(shè)備制造商和一級供應(yīng)商均信賴這種工藝技術(shù)。“我們提供從機(jī)床到夾具的整套交鑰匙產(chǎn)品。所有組件都已完美協(xié)調(diào)匹配。我們所有的研發(fā)工作都以豐富的實(shí)踐經(jīng)驗(yàn)為基礎(chǔ),這些優(yōu)勢將在市場上得到認(rèn)可,”Loporchio 總結(jié)說。

Successful in the marketplace

In recent years, this slim and efficient approach has enjoyed ever greater success: 60 to 70 EMAG production lines with a total of around 250 turning machines are already in use around the world in the production of differential cases. OEMs and tier 1 suppliers rely on this technology. “We offer the complete package, from machine to clamping device. All the components are perfectly matched. Also, all our development work is grounded in a lot of practical experience. These advantages are gaining recognition in the marketplace,” says Loporchio in conclusion.

相關(guān)信息請見:Https://www.emag.com/de/werkstuecke/differenzialgehaeuse.html 或者親臨 2018 年 AMB 展會 4 號展廳、4B51 號展臺。

You will find more information here: https://www.emag.com/de/werkstuecke/differenzialgehaeuse.html or during a personal meeting at the AMB 2018 at Stand 4B51 in Hall 4.

根據(jù)工件/工藝技術(shù)要求,在收到訂單后約 6 個月,便可向客戶交付一套完整的差速器生產(chǎn)線模塊化解決方案。

A complete differential line based on the Modular Solutions building block can be delivered in only around 6 months after receipt of the customer's order—depending on the component or the technological requirements.

第一面和第二面的車削(OP 10 和 20)在埃馬克 VL 機(jī)床上進(jìn)行,OP 30 在埃馬克 VT 機(jī)床上進(jìn)行。

The first and second sides (OP 10 and 20) are turned on a VL machine, while OP 30 is performed on a VT machine from EMAG.

使用埃馬克的 TrackMotion 系統(tǒng)時,配備可編程電動機(jī)械手的升降翻轉(zhuǎn)滑臺可在各臺機(jī)床之間的軌道 (Track) 上來回穿梭。

With the TrackMotion system from EMAG, a lifting and flip-over carriage with programmable electric gripper runs back and forth on a track between the machines.

另外,高精密特殊夾具也由埃馬克自行研發(fā)。這里展示的是 OP 40 中的 VL 6 車削中心。

The high-end special clamping devices are also developed in-house by EMAG. In this case for the VL 6 turning center in OP 40.